In the tooling phase of thermoforming a single 3D form is created out of aluminum, wood, polyurethane, or a 3D printer. In injection molding, a double-sided 3D mold is made from aluminum, steel, or beryllium-copper alloy. There is an advantage in timing and price with thermoforming since prototype samples can be made from CNC cut wood tooling. Tooling costs for large product tooling are substantially less with thermoforming.

除濕幹燥機(蜂巢型)

用於原(yuán)料幹燥(zào),可滿足99%原料幹燥需求,隻限於注塑行業。

除濕幹(gàn)燥(zào)機(jī)(標準型)

注塑原(yuán)料幹燥除濕機適用於注塑行業,集(jí)除(chú)濕、烘幹、輸送原(yuán)料功能為(wéi)一體的設備,屬於首熙自研設備。

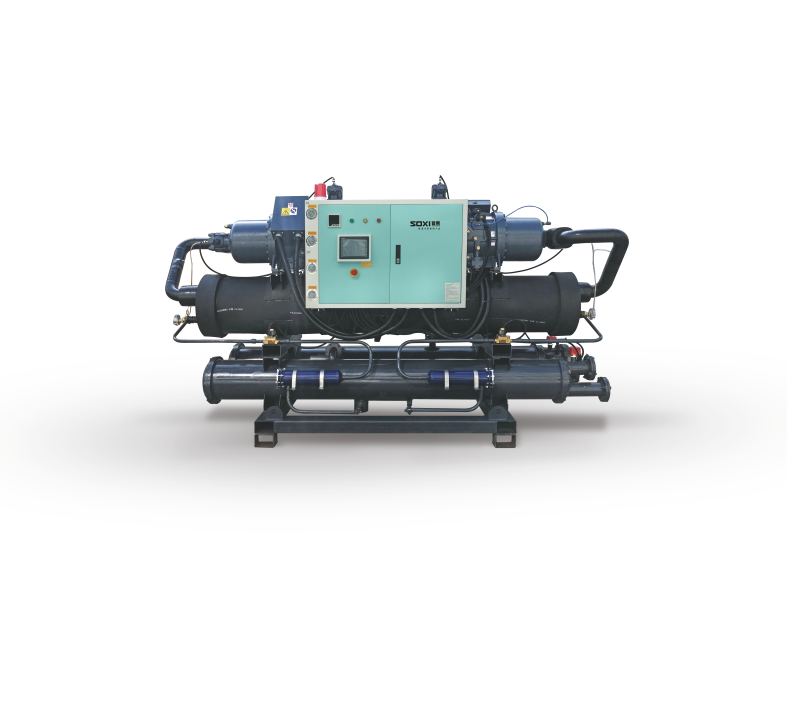

水(shuǐ)冷式冷水機

適用於注塑機水溫(wēn)冷卻,讓設備快速降溫提高產品合格率

配比機(稱重(chóng)式(shì))

它(tā)通過精確配比原料、高效混合原料、提(tí)升(shēng)產品質量、降低生產成本以及實現(xiàn)智能化和(hé)自動化控製等方麵

配比機(體積式)色母機

體積式配比(bǐ)機,可存儲五十種配比配方

小型(xíng)立式拌料機

拌料機,適用於注塑行業

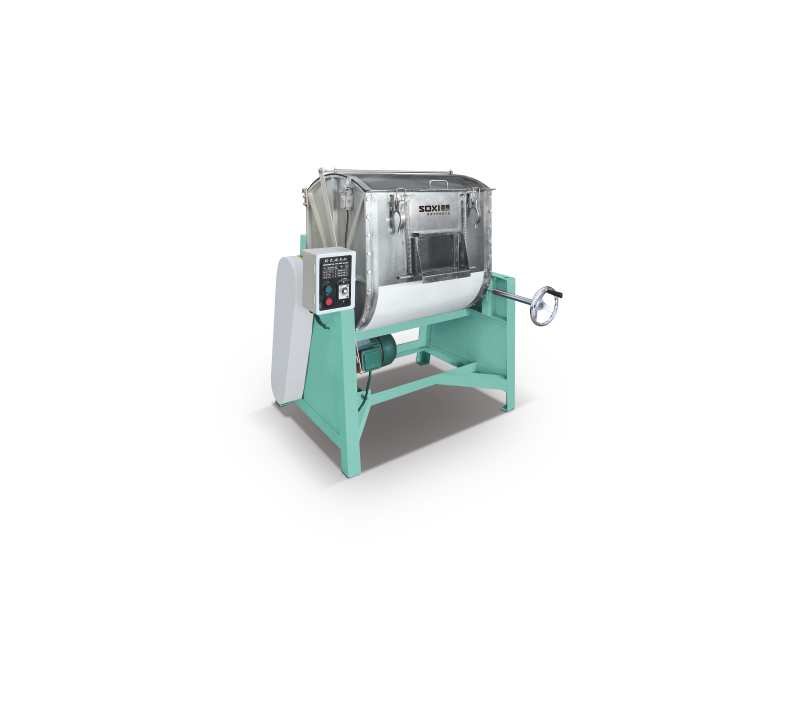

大型拌料機

儲料(liào)拌料為一體的拌料機

模溫機

模具溫(wēn)度控製設備

暫無數據.No Data.

English

English

.PNG)

.PNG)

_r__787-708_c__3e444a_.PNG)

.PNG)

_r__708-669_c__c9cfc5_.PNG)

_r__708-669_c__a7bfb7_.PNG)

_r__708-669_c__89bdb5_.PNG)

.PNG)

.PNG)